Anyway, I would suggest you just create a simple test database/product system to understand how openLCA calculates and scales analysis results.ġ) Create two very simple processes with custom flows that are easy to trackĢ) Build the corresponding product system:ģ) Build an LCIA method that captures the respective flowsĤ) Calculate the analysis results and check how openLCA calculates the impact analysis results from the life cycle inventory openLCA features dependent parameters but they are clearly different from what you use the term for. I am confused by your use of the term 'dependent parameter'.

Is OpenLCA scaling the flows F1, F2, F3 and F4 (dependent parameters) in function of this 15.000.000 m3? How can I check this calculations?

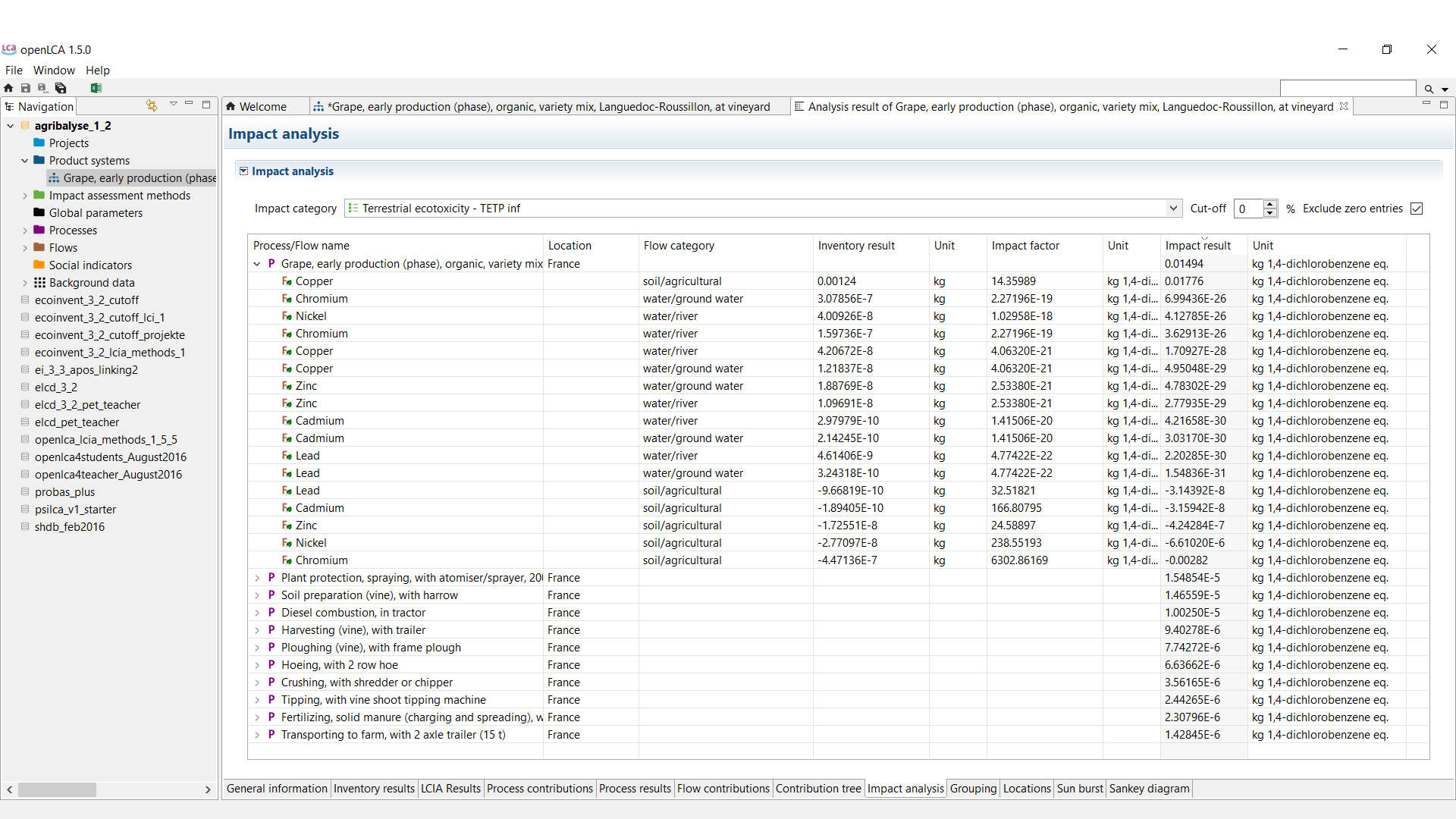

I gave F5 the value 1 m3 of processed water.Īfter that, I created a product system for water treatment and calculate the CO2 emissions (GWP) asociated for 15.000.000 m3 of processed water (output value), but i don´t understand how OpenLCA calculate the emissions, because when I checked the parameters value (flows of water) in each operation process (T, PT, ST, D), they keep being the same value defined for 1 m3 of processed water. I modeled each flow as a dependent parameter, for example, flow F1 enters process (T) and depends of F2, flow that exits process (T) and enters porcess (PT).finally F4 enters process (D) and F5 is the processed water that leaves the process, so F1 is a function that depends of F5. The water flow that leaves one process enters the next one and each process has some water losses asociated. I´m modelling a virtual water treatment process wich consist in four operations: pre-treatment (T), primary treatment (PT), secondary treatment (ST) and desinfectation (D), in that specific order.

0 kommentar(er)

0 kommentar(er)